Automatic machine for inclined drilling

DESCRIPTION OF THE EMR2/D65 MACHINE

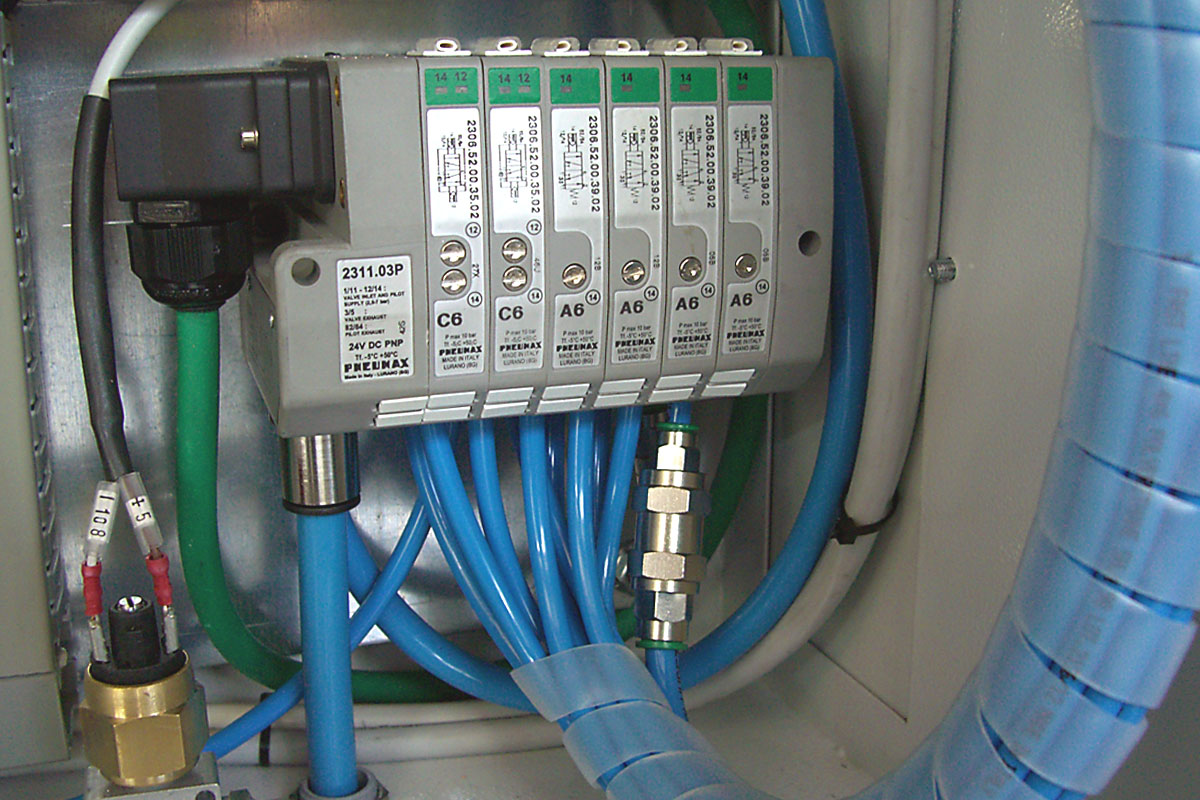

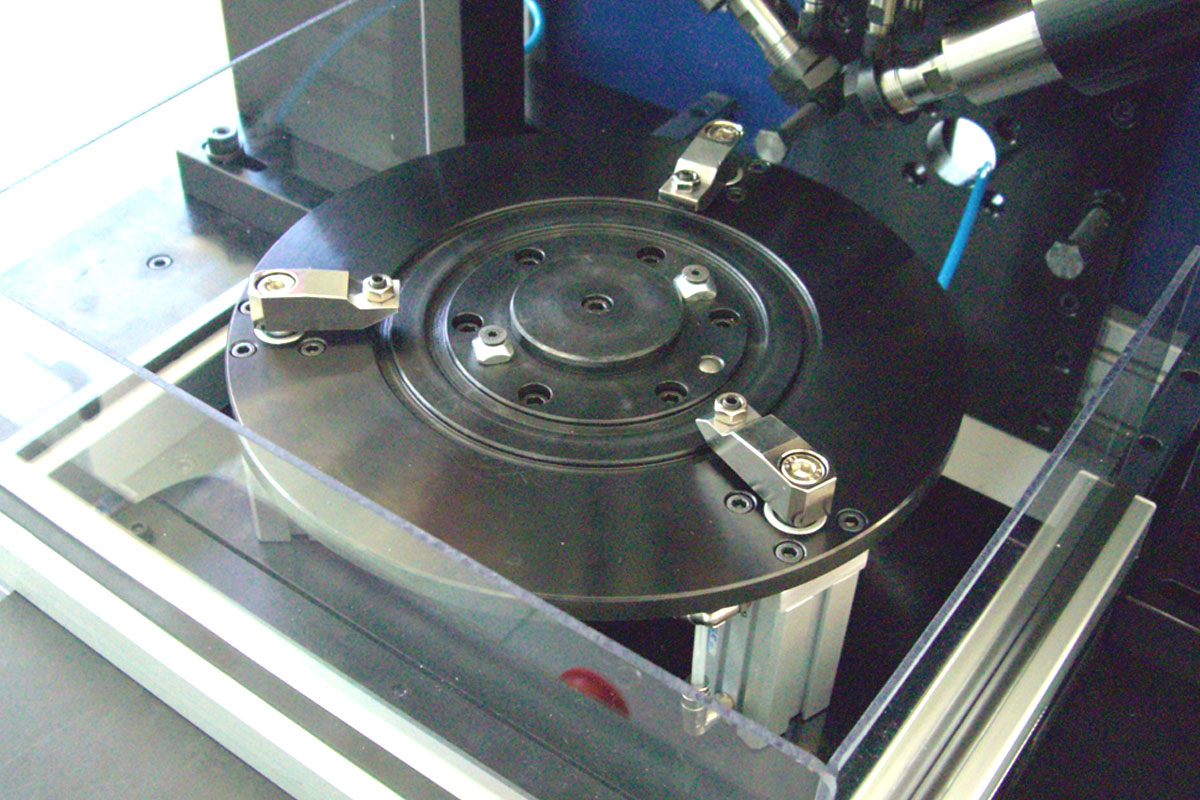

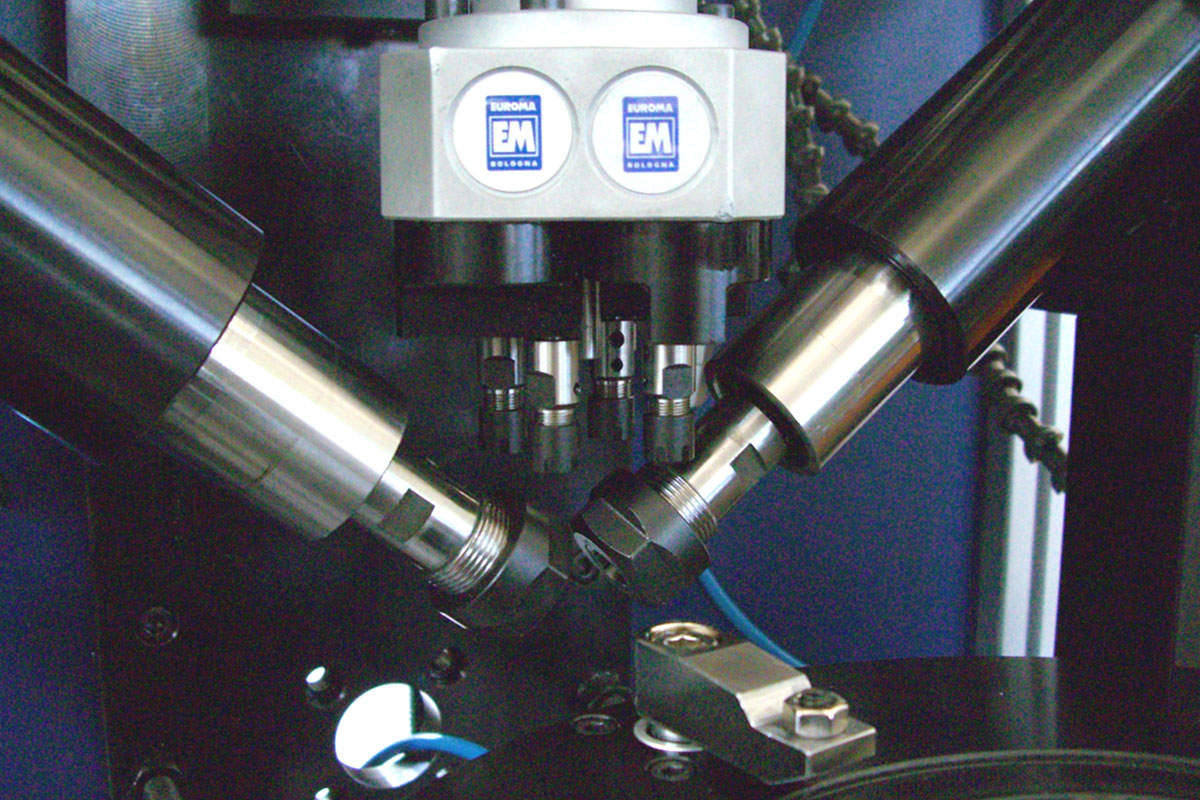

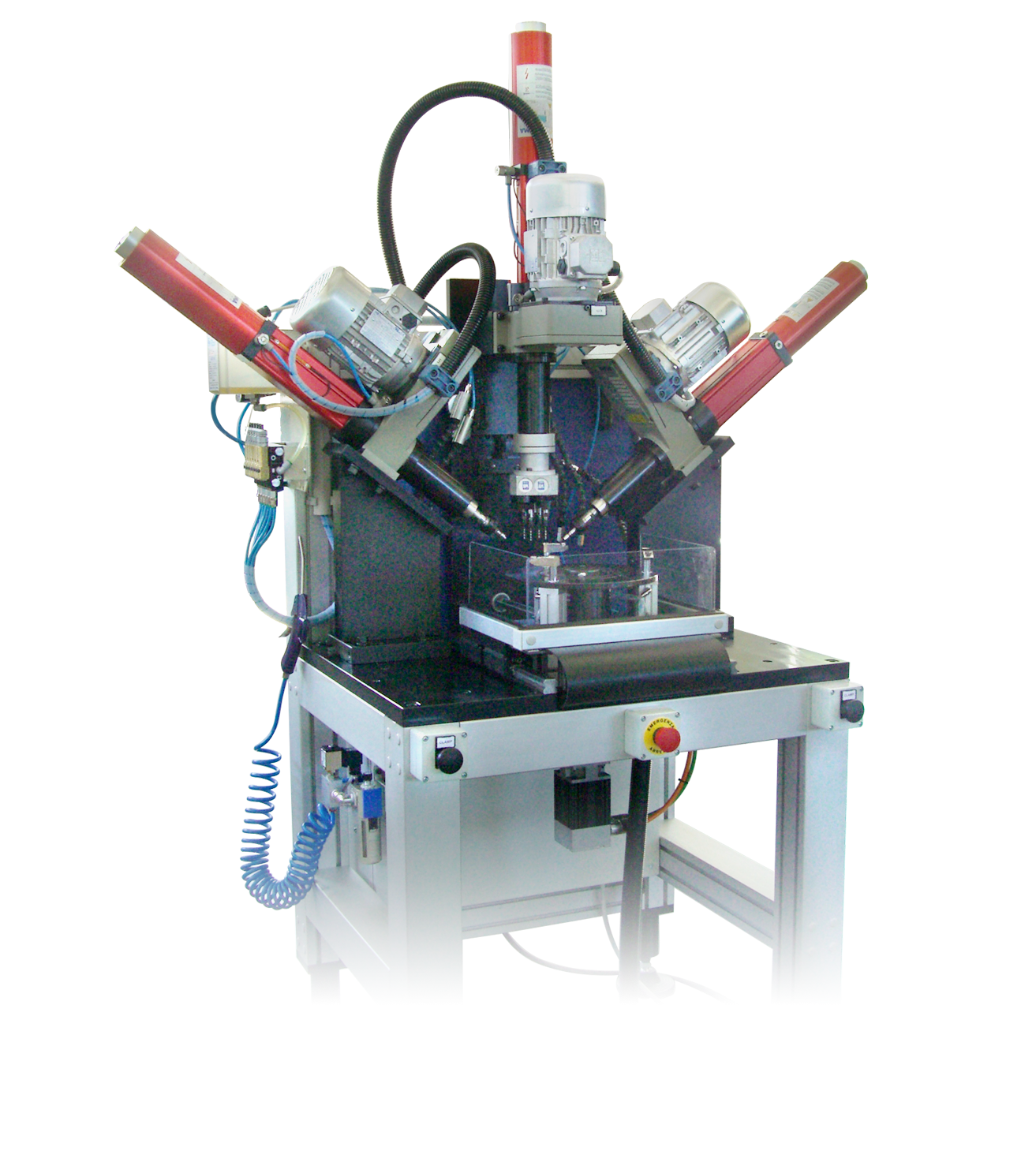

Electro Mac Srl has specialized in the production of machinery for processing metals for over fifty years and is therefore able to offer highly technological, extremely reliable systems to the industrial sector. A clear example of innovation combined with functionality and simplicity is the EMR2/D65 machine for fully automatic inclined drilling. It includes three work units. The system consists of an aluminium supporting structure with a 90 x 90 section complete with a flat aluminium base with a thickness of 30 mm. The middle part designed for rotation is electronically controlled. The different positions can be scheduled and set according to the holes to be made on the workpiece. The machine is equipped with a BRUSHLESS motor and epicycloidal step-down gears with a reduction ratio of 1/30, electronic guides and electronic board control. The EUROMA drilling unit model FPx13.75 mounted on the EMR2/D65 system is equipped with a multiple head with 4 adjustable pins model V4.044P with a size of min. 29.5mm x max 89.5 mm.

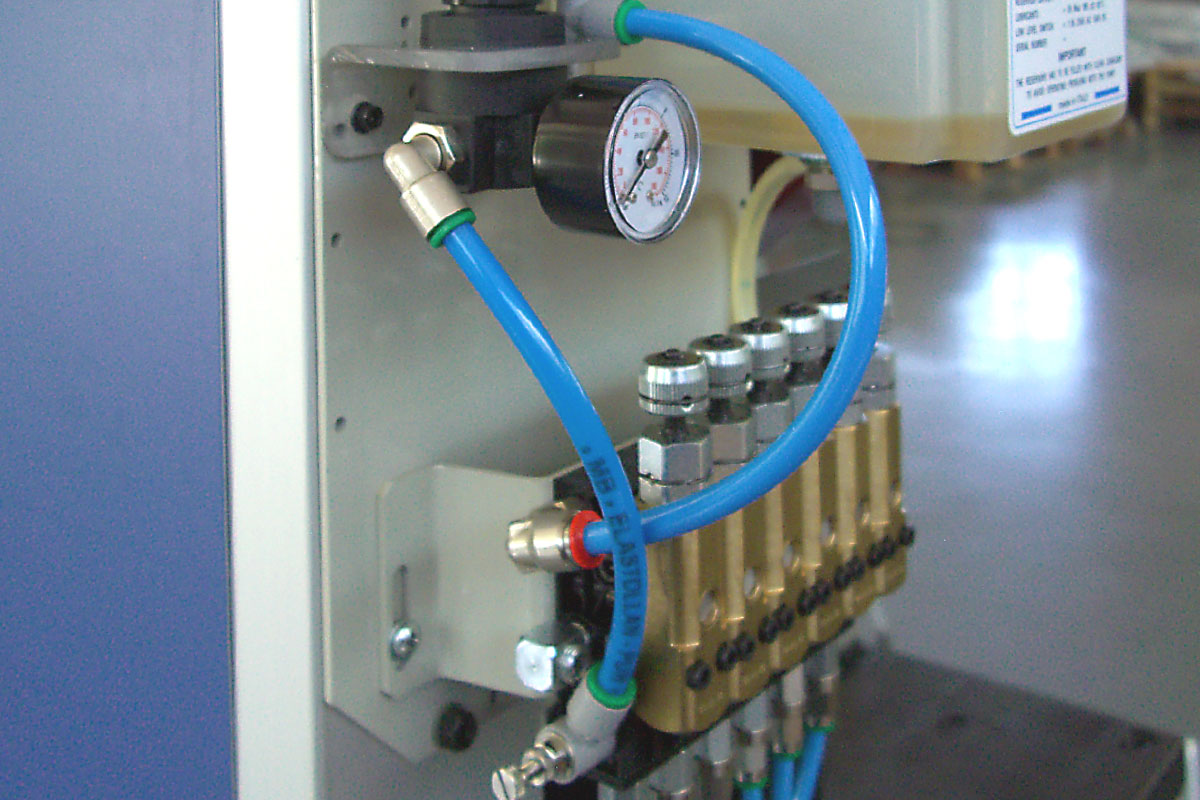

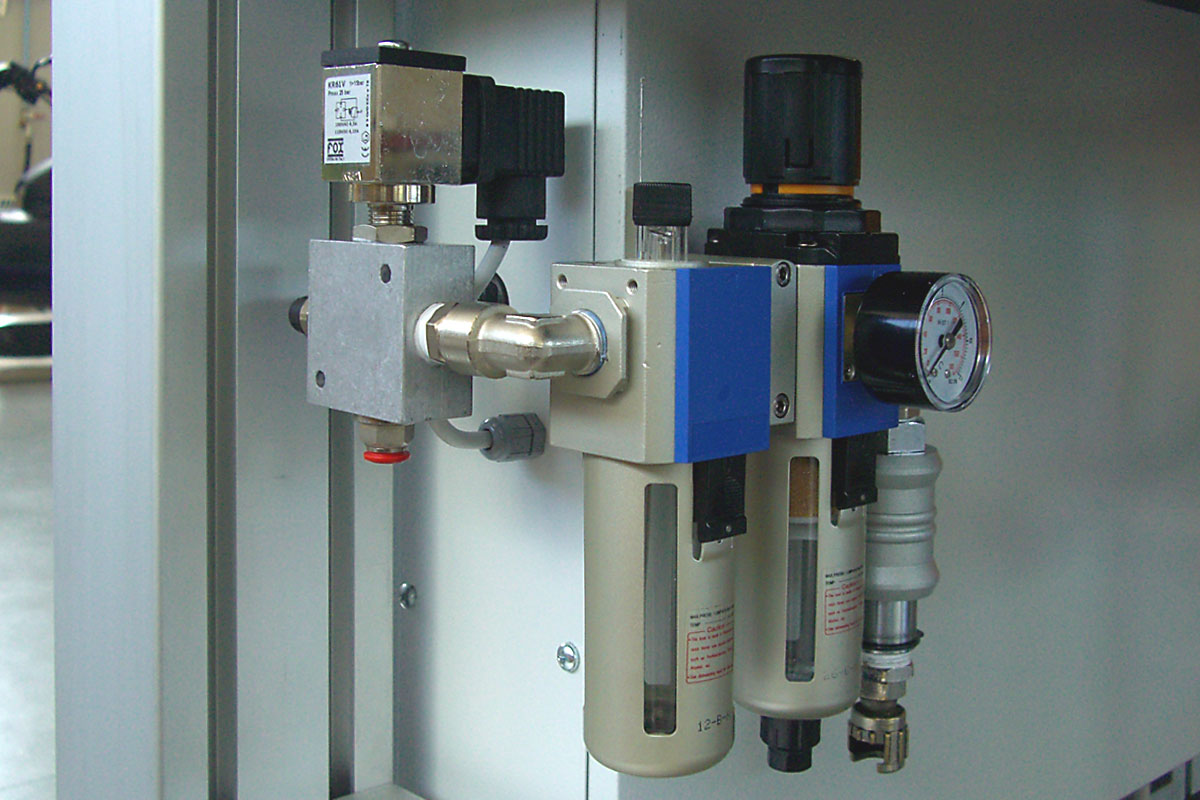

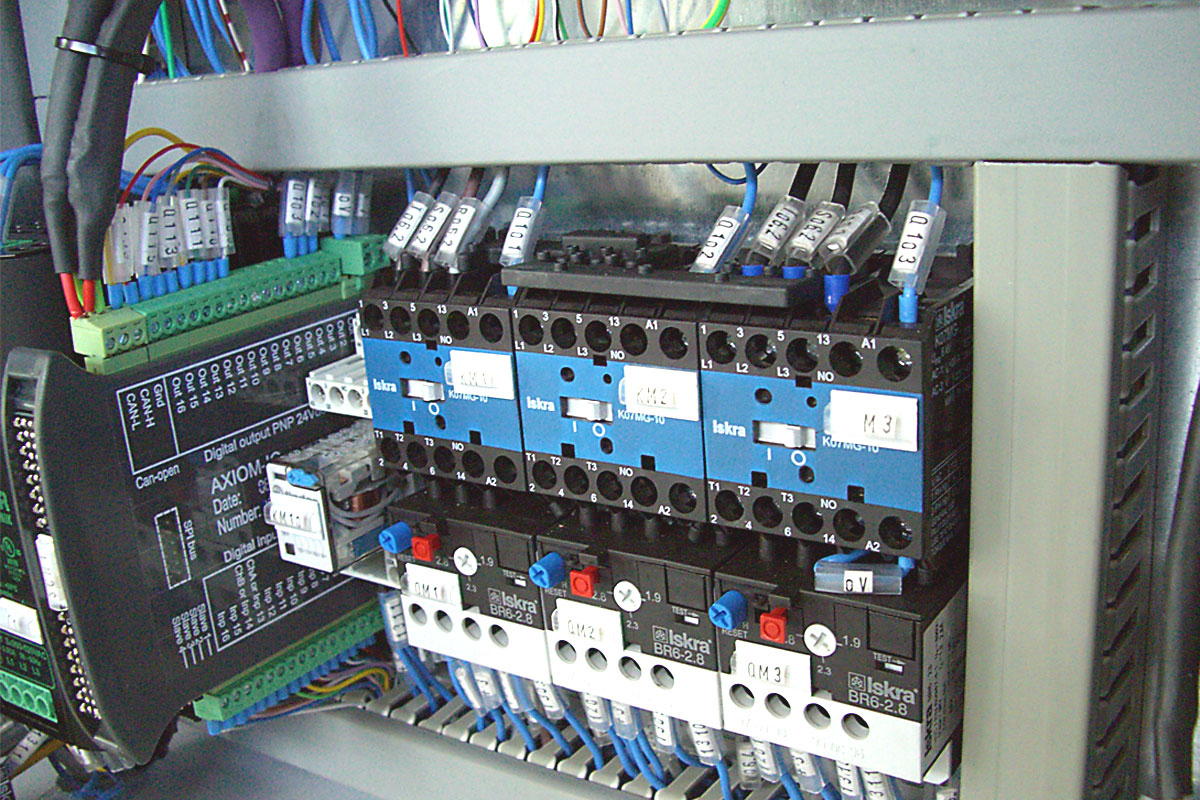

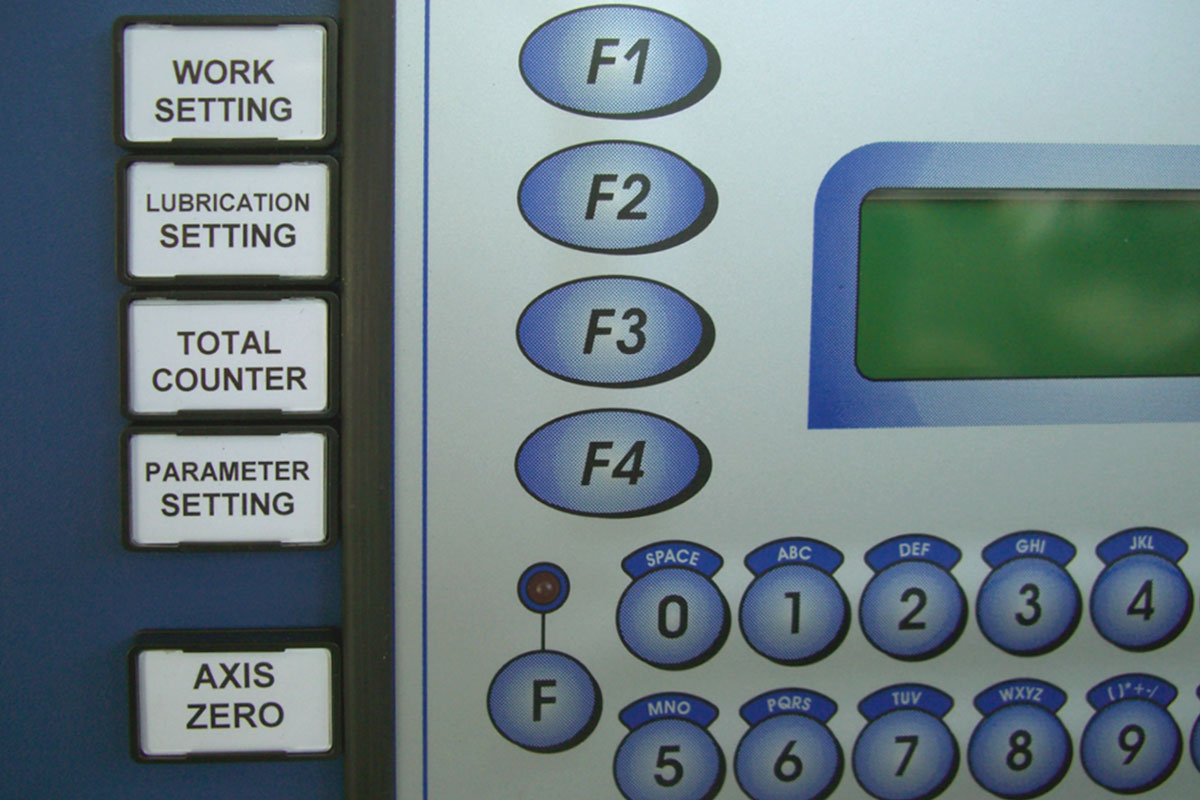

A suitable pneumatic unit makes the blocking of the workpiece being processed possible. An advanced rotation axis control system makes an optimal automatic management of the production cycle possible. There is also a tool for the automatic lubrication of the whole EMR2/D65 machine by means of a system equipped with a pump and a 5 litre tank. A backlit numeric display, the push buttons and the warning lights make visual monitoring of the whole electronic control panel installed on this metal inclined drilling machine possible. The experience acquired by the Electro Mac Srl company over many years of work in the metal foundry sector has been put at the service of the industrial sector. This Company is now able to offer the market products with high added value, such as the EMR2/D65 drilling machines. They simplify the operations for creating inclined holes significantly. Multiple holes can be drilled on pipes, bars and profiles with very different shapes and dimensions. The execution of this work with traditional machines would definetly be very difficult.

APPLICATIONS

- Drilling pipes

- Drilling tubular units

- Drilling profiles

- Drilling laminated plates

- Drilling steel components

- Drilling finished products

ADVANTAGES

- Maximum safety

- High productivity

- Fully automatic management

- High drilling precision

- Different drilling positions and inclination