We are specialized in shell casting, which is one of the most ancient metal processing methods.

The Electro Mac Srl company has been focusing on customers and on their production requirements for more than sixty years. The company keeps investing in research and development in the field of technologically advanced solutions in order to face all the different challenges of the market of shell gravity casting of brass and of other alloys. Electro Mac Srl is located in the Brescian valleys, which are the centre of one of the most prominent and oldest metallurgic area. It is specialized in shell casting, which is one of the oldest metal processing methods. This shell casting method involves melting brass in furnaces at a very high temperature. This high temperature keeps the

metal in the liquid state until gravity casting into the moulds takes place. After solidifying, the metal takes up the desired shape. The whole procedure leading to the production of finished pieces is carried out internally in order to guarantee optimal control of quality, effectiveness and of the technical and visual characteristics of the product manufactured. This procedure includes an accurate study of the project, the analysis of the most suitable technical solutions and a selection of top quality raw materials.

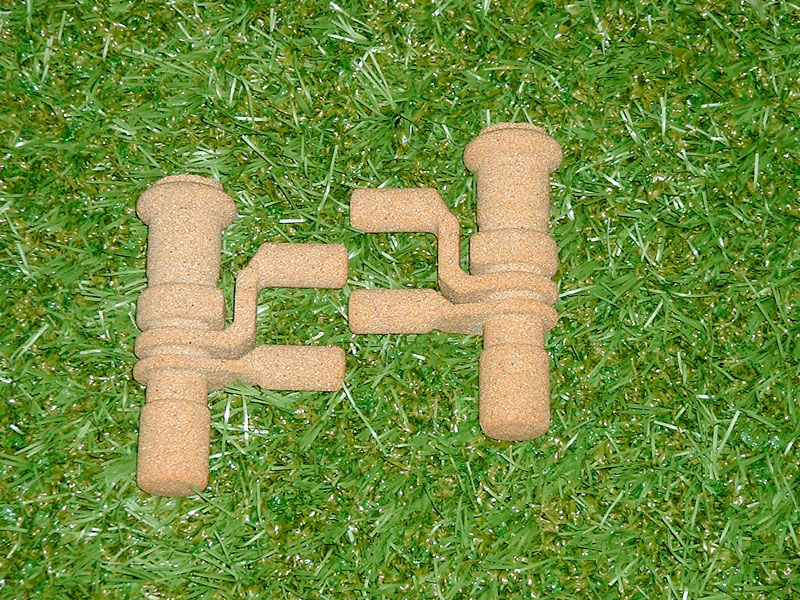

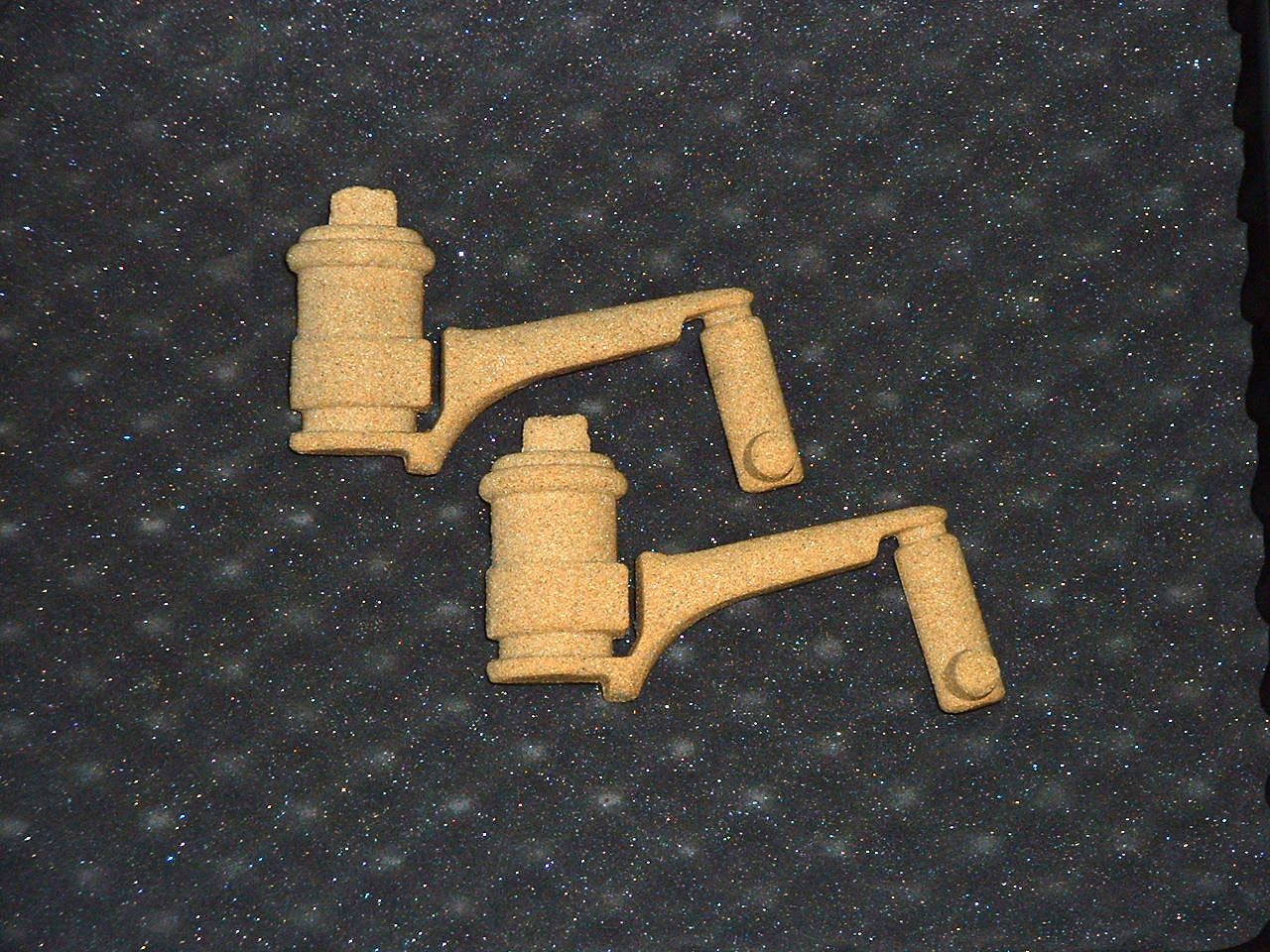

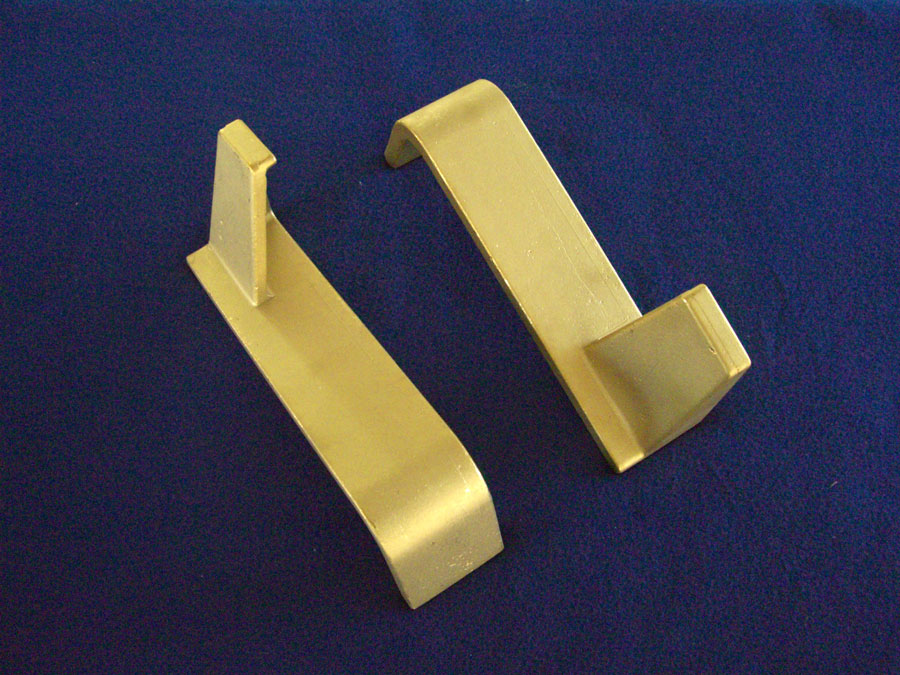

Brass shell gravity casting

The shell gravity casting of brass enables Electro Mac Srl to supply to its customers accessories,

components, processed and semi-finished products of different types for very different applications: taps, valves, fittings, components for the oil and gas sector, manifolds, furniture, artistic products, mechanical and electromechanical products and precision mechanical and electromechanical products. Each product brought into the market by the foundry is made of top quality metal materials which are carefully selected all over Europe and accompanied by a certificate of origin in order to guarantee transparency and clarity, which the Company wishes to assure to its counterparts.